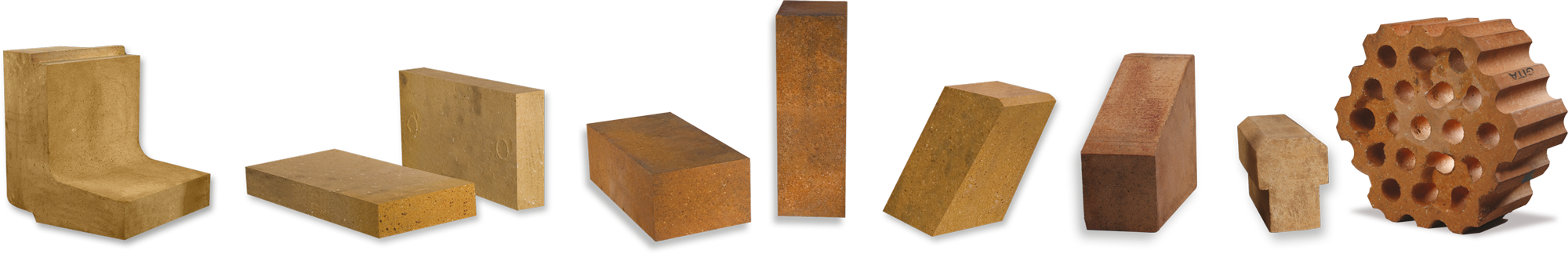

Alumina Refractory Bricks

High-alumina refractories are made from bauxite, a naturally occurring material containing aluminum hydroxide Al(OH)3 & kaolinitic clays. These raw materials are roasted to produce a mixture of synthetic alumina & mullite (an aluminosilicate mineral with the chemical formula 3Al2O3 – 2SiO2). By definition high-alumina refractories contain between 50% & 90% alumina. They are much more robust than fireclay refractories at high temperatures & in basic environments. In addition, they exhibit better volume stability & abrasion resistance. High-alumina bricks are used in blast furnaces, blast-furnace stoves, and liquid-iron ladles etc.

Advantages

- Excellent corrosion resistance to neutral and acidic slag and metal penetration resistance at high liquid temperature.

- Improved thermal shock and corrosion resistance at high temperature.

- Low Thermal Conductivity

- Low Thermal Expansion

Dense Alumina Bricks

| Brand | Al2O3 % (Min) | Fe2O3 % (Max) | BD gm/cc (Min) | AP % (Max) | CCS kg/cm² (Min) | PCE Orton Cone (Min) | RUL Ta°C (Min) | PLC % (Max)/2hrs | Service Temp.°C Max | Application Area |

|---|---|---|---|---|---|---|---|---|---|---|

| GITA - 30D | 30 | 2.3 | 2.00 | 20-22 | 350 | 30 | 1350 | ±1 @ 1350 °C | 1350 | Coke Oven and Blast Furnace Battery |

| GITA - 35D | 35 | 2.3 | 2.05 | 20 | 350 | 32 | 1350 | ±1 @ 1350 °C | 1400 | For Blast Furnace |

| GITA - 39 HG | 39 | 1.8 | 2.10 | 18-20 | 400 | 33 | 1450 | ±0.5 @ 1450 °C | 1400 | BF (upto @ 700 M3 ) Hearth & Bottom, Hot Metal Ladle |

| GITA - 40 HG | 40 | 2.0 | 2.10 | 18-20 | 400 | 33 | 1450 | ±0.5 @ 1450 °C | 1400 | BF stove @ Wall Brick (upto 700 M3) Coke oven Battery |

| GITA - 42 HG | 42 | 1.8 | 2.20 | 18-20 | 400 | 33 | 1450 | ±0.5 @ 1450 °C | 1430 | BF (upto @ 700 M3) Hearth Bottom Belly & Ladle, Cake Oven Battery |

| GITA - 45 D | 45 | 1.8 | 2.20 | 18 | 450 | 33 | 1450 | ±0.5 @ 1450 °C | 1450 | BF (upto @ 700 M3) Bosch & Tuyer zone, Coke Oven Battery |

| GITA - 50D | 50 | 1.5 | 2.30 | 18 | 450 | 34 | 1500 | ±0.5 @ 1500°C | 1450 | For Coke Oven Battery |

Medium Alumina Bricks

| Brand | Al2O3% (Min) | Fe2O3% (Max) | BD gm/cc (Min) | AP % (Max) | CCS kg/cm² (Min) | PCE Ortton Cone (Min) | RUL Ta °C (Min) | PLC % (Max)/ 2hrs | Service Temp. °C Max | Application Area |

|---|---|---|---|---|---|---|---|---|---|---|

| GITA - 40 | 40 | 3.5 | 2.05 | 25 | 300 | 32 | 1350 | ±1.5 @ 1400 °C | 1400 | General Purpose upto 1400 C, Saftey lining of steel ladles |

| GITA - 45 | 45 | 3.5 | 2.15 | 22 | 350 | 32 | 1400 | ±1 @ 1450 °C | 1400 | General Purpose upto 1400 C, Heat Treatment Units, Forging Units & Hot Metal Ladle |

| GITA - 50 | 50 | 3.5 | 2.30 | 22 | 350 | 33 | 1400 | ±1 @ 1400 °C | 1450 | General Purpose Safety Line refractories |

High Alumina Bricks

| Brand | Al2O3% (Min) | Fe2O3% (Max) | BD gm/cc (Min) | AP % (Max) | CCS kg/cm² (Min) | PCE Ortton Cone (Min) | RUL Ta °C (Min) | PLC % (Max)/2 hrs | Service Temp. °C (Max | Application Area |

|---|---|---|---|---|---|---|---|---|---|---|

| GITA -HA- 60 | 60 | 3.5 | 2.4 | 23 | 400 | 34 | 1450 | ±1 @ 1450 °C | 1500 | Walls, Bottom, & Roof of reheat furnaces, Soaking pit walls and annealing furnaces |

| GITA-HA - 70 | 70 | 3.5 | 2.6 | 23 | 500 | 36 | 1470 | ±2.5 @ 1450 °C | 1550 | Working lining of steel ladle up to 60 T capacity |

| GITA-HA - 80 | 80 | 2 | 2.7 | 20 | 600 | 38 | 1600 | ±2 @ 1500 °C | 1650 | Working linining for RF/VAD/VOD |

Special High Alumina Bricks

| Brand | Al2O3% (Min) | Fe2O3% (Max) | BD g/cc (Min) | AP % (Max) | CCS kg/cm² (Min) | PCE Orton Cone (Min) | RUL Ta °C Min | PLC % (Max)/ 2hrs | Service Temp.°C Max | Application Area |

|---|---|---|---|---|---|---|---|---|---|---|

| GITA - 62D | 62 | 1.5 | 2.50 | 16 | 600 | 36 | 1550 | ±0.5 @ 1500 Deg°C | ±0.5 @ 1500 Deg°C | For blast furnace bottom |

| GITA Silimanite | 58 | 0.5 | 2.50 | 18 | 600 | 37 | 1600 | ±0.3 @ 1600 °C | 1700 | Blast Furnace & Glass Tank |

| GITA - 70(S) | 70 | 2.5 | 2.60 | 18 | 600 | 37 | 1550 | ±1.5 @ 1500 Deg°C | ±1.5 @ 1500 Deg°C | Working lining of steel ladle for high capacity |

| GITA-MULLITE | 70 | 0.5 | 2.60 | 20 | 600 | 37 | 1650 | ±0.3 @ 1600 °C | 1650 | Blast Furnace & Glass Tank |

| GITA - 72D | 72 | 1.0 | 2.65 | 18 | 600 | 38 | 1650 | ±0.5 @ 1500 Deg°C | ±0.5 @ 1500 Deg°C | Blast Furnace & Fertilizer Units |

| GITA - 85 | 85 | 1.5 | 2.80 | 18 | 500 | 38 | 1600 | ±0.5 @ 1500 °C | 1680 | Sponge Iron, Fertiliser Units |

| GITA - 90 | 90 | 0.5 | 2.90 | 18 | 900 | 40 | 1700 | ±0.2 @ 1600 °C | 1750 | EAF Roof, Fertilises & Petrochemical Industries |